- Client:

- Cargotec

- Date:

- April 2012

- Scope of work:

- Design, Manufacture, Installation, Commission

- Location:

- Teesside UK & Portland USA

- Specs:

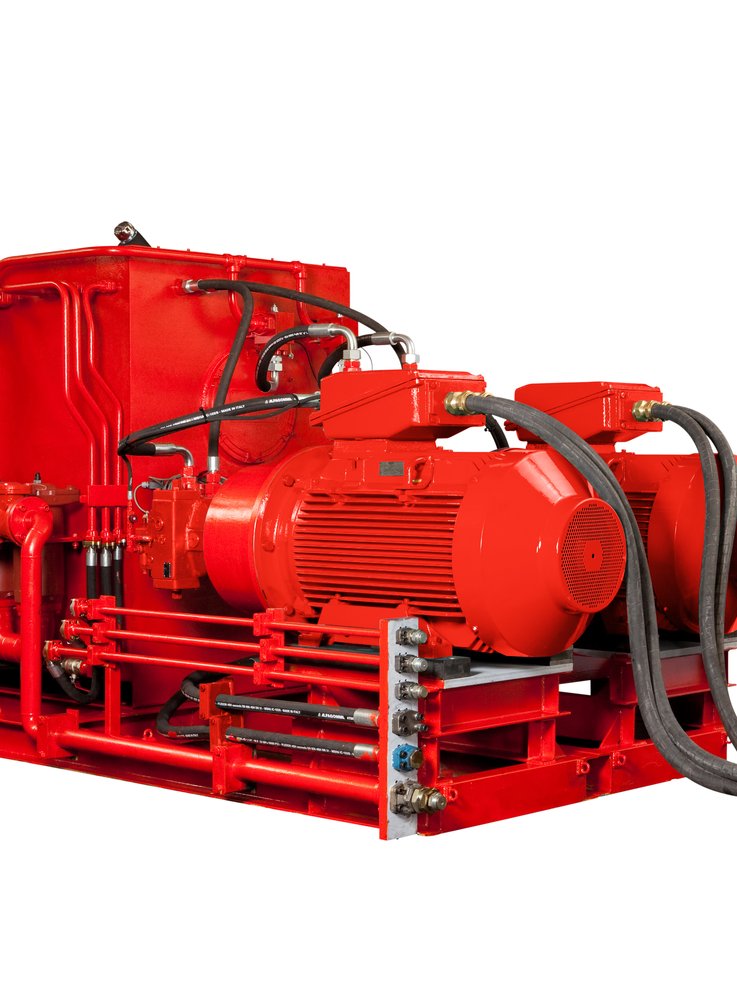

400kW, 600L, 350 bar.

Modular design to enable airfreight.

3.5 weeks from enquiry to delivery.

DEEP WELL CAPPING STACK WINCH SYSTEM

- Overview:

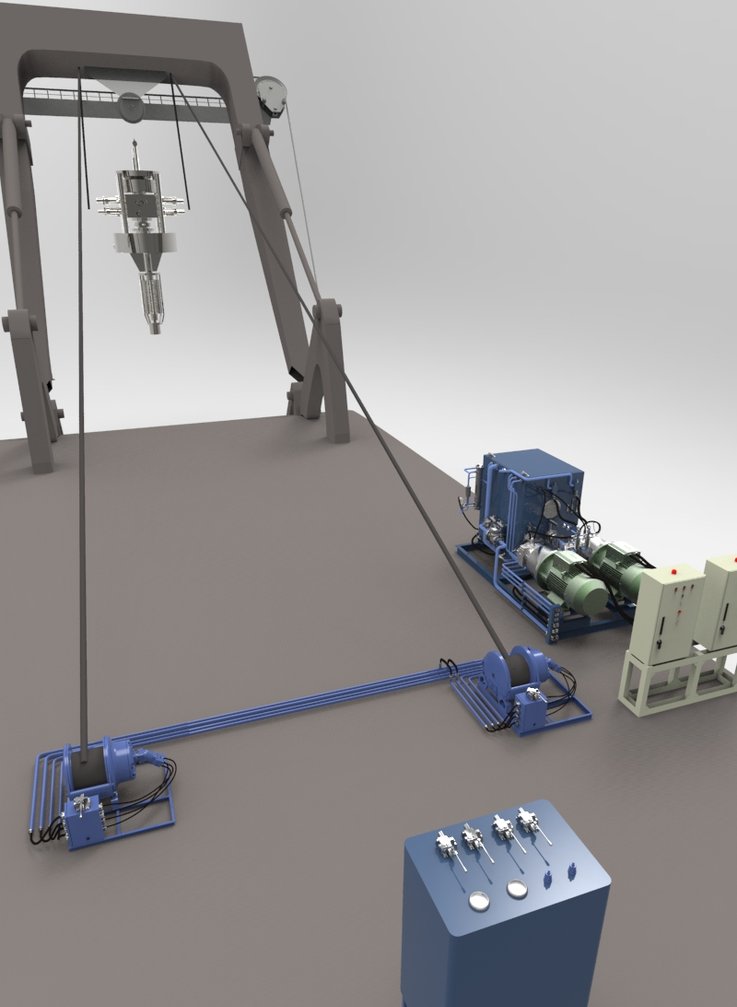

In response to the Deepwater Horizon oil spill in the Gulf of Mexico in 2010, Shell has developed a new mobile solution to enhance BOP automation and sealing systems to avert another environmental catastrophe in the event of deep well blowout.

Mobile capping systems are equipped with hydraulic rams to match the pressure of the liquids gushing out of the well. They are designed to travel to the location of the blowout and be lowered into place using hydraulic systems to suppress wave action. The aim of a well capping system is that a module can be taken to any deep water well in the world and installed within 10 days.

Working to an extremely tight deadline, Cargotec/MacGregor commissioned IMH to design and manufacture at our base in Teesside a 400kW hydraulic power unit to drive the winches that will stabilise the BOP as it is deployed from the vessel. The project was carefully designed, procured and manufactured in 3.5 weeks, to a modular design, and airfreighted to the USA, where our IMH Engineer met the icebreaker ‘Fennica’ for installation and commissioning. The system will be based in Alaska for emergency deployment in Arctic Waters.

Benefits to the Client:

– Reliability to deliver the project to an extremely tight deadline.

– Company flexibility enabling us to take on the project at very short notice and coordinate with the company’s busy schedule with confidence that we could deliver.

– Cost-effective solution.

– Experienced marine project engineering team providing hydraulic solutions to complex problems across the marine and offshore industry.