- Client:

- Rexroth

- Date:

- 1987

- Scope of work:

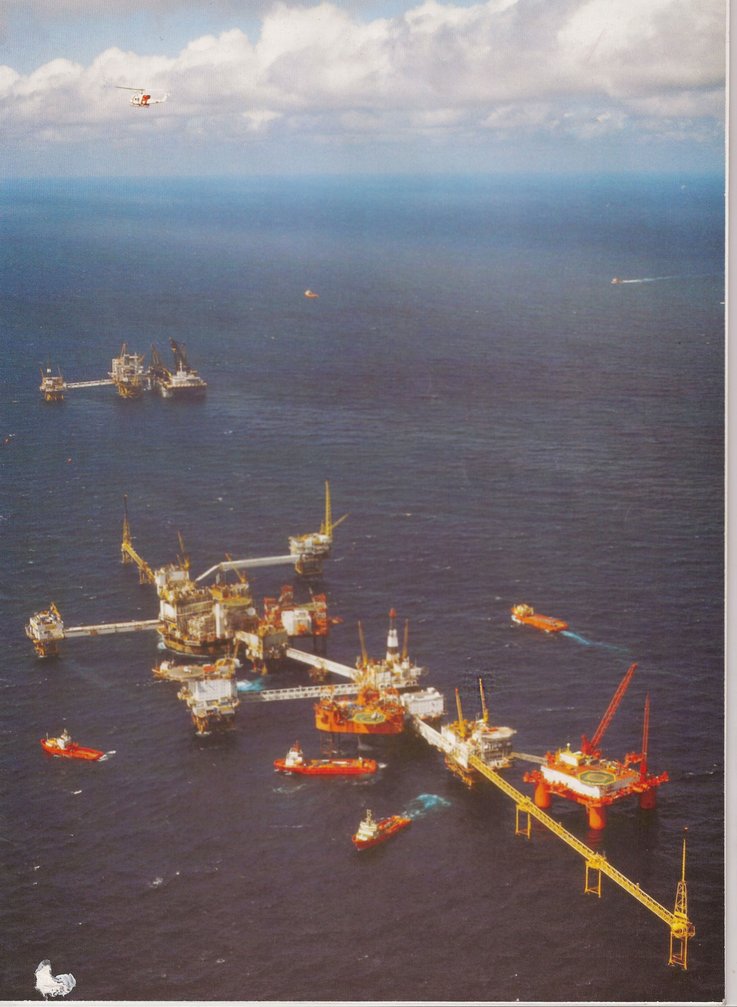

- North Sea, Norwegian Sector

- Location:

- North Sea, Norwegian Sector

- Specs:

41,000 tonne lift across 6 platform complex.

Largest lift in the world at the time.88 x 700 tonne jacks

18 x 180 tonne jaks

17 x 3000 litre HPUs

170 x 1500 litre HPUs

25 x 600 litre HPUs

DECK ELEVATION PROJECT FOR OIL PLATFORM FIELD SUBSIDENCE

- Overview:

The Ekofisk ‘Jack Up’ project was the subject of one of the most difficult and demanding sea rescue operations ever attempted at the time. The platform discharged 200,000 barrels per day alone to the Phillips complex at Teesside, making this internationally significant project, also a local one.

Due to sea bed subsidence, the Ekofisk complex in the North Sea was sinking by approximately 40cm/yr and had reduced the safety air gap of 20m to 16.3m between the platform decks and storm waves. In order to compensate for the subsidence of six platforms, the ‘jack up’ project was born with a criteria to create a 23m 100 year ‘design wave’ by extending the platform legs and raising the decks 6m.

This was the largest lift and most prestigious project in the world at the time with a total value of £400 million, and for IMH Commissioning Engineers the most challenging and rewarding undertaken at that time.

The lifting operation had to lift all platforms simultaneously because of the many existing interconnecting bridges and pipelines. The method entailed cutting the platform legs whilst powerful hydraulic jacks were clamped to the legs to hoist the platform of almost 41,000 tonnes of metal into the air. Support spools of 6m in length were fitted into the gap to restore a permanent and safe degree of water clearance.