- Client:

- Centregreat

- Date:

- 2023 – September 2024

- Scope of work:

- Design, manufacture, installation and commissioning of a hydraulic system as part of an upgrade to the flood defence at Truro.

- Location:

- Truro, Cornwall, UK

- Specs:

Flood defense hydraulic system designed to DIN19704

TRURO TIDAL GATE

- Overview:

Truro Tidal Gate is a strategically important asset that plays a critical role in managing flood risk and protecting 45 homes and 140 businesses in the Cornwall commercial capital of Truro.

The gate provides protection from tides of a certain magnitude during high river and surface water flow. Having not benefitted from major capital maintenance, testing identified that elements had become worn, obsolete and reached the end of their serviceable life and therefore required replacing.

The project to install the new tidal gates began in 2023 and a key spot on the Truro River was selected in order for the project to take place during low tide, negating the requirement to close the gates. However, contingencies were put in place in the unlikely event that the gates would need to be operated, which would involve the installation of temporary flood barriers – stop logs at the gate structure.

Delightedly, contingency was not required during the project and during the 16,000 hours on the job there were no serious incidents recorded.

Main Contractor:

Kier

End User:

The Environment Agency

Scope of work:

Having previously worked with the Environment Agency on numerous flood gate projects, our team’s expertise was readily available to support the tidal gate project in Truro.

Working closely alongside other parties involved, including Kier Natural Resources, Nuclear & Networks, AtkinsRéalis and Centregreat Engineering, we engineered a hydraulic solution that operated using biodegradable fluid.

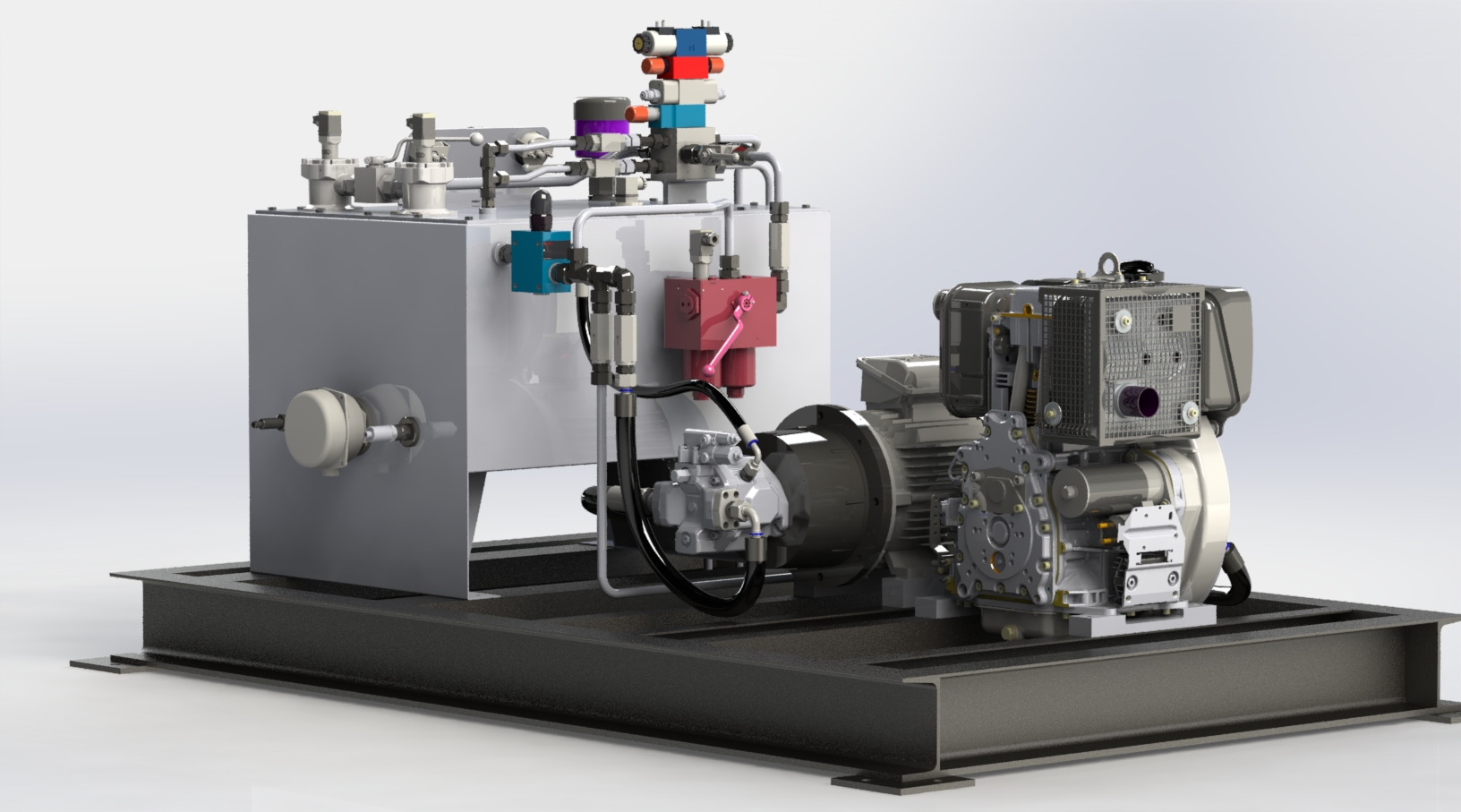

The IMH team utilised its vast hydraulic experience to design a hydraulic system on specialist software HydroSYM and then created the mechanical drawings on SolidWorks.

The hydraulic system designed is based on the BS EN ISO 4413 – Hydraulic Fluid Power General Rules & Safety Requirements for Systems and their Components. It comprised of a 7.5kw electric motor-powered hydraulic pump for normal operation as well as a diesel engine operated pump, which can be used in the event of an electrical power failure.

In addition, the system can also be put into a ‘float mode’ to allow the gates to be manually operated in the event of an emergency.

It takes just 2 minutes 20 seconds to open the gate and 1 minute 40 seconds to close – providing a fast response to any rises or fluctuations in tide flow.

All of the pipe work Take-Over-Points (TOP) on the hydraulic power unit (HPU) was configured to suit the specific site conditions and the layout of the hydraulic equipment. This resulted in no crossover of the pipelines during installation and delivered a more aesthetic appearance of the pipe work.

Additionally, each TOP was equipped with an isolation valve with a padlock able to be used in its fully open and fully closed positions.

The system pressure gauges were provided within the HPU design in stainless steel casing and panel mounted and in order to prolong their working life, they were glycerine filled and have a maximum pump pressure of 138 bar.

Each function is individually controlled by dual solenoid operated directional control valves, mounted directly to a manifold located on the tank lid. And to prevent potential damage to the mechanical structure each function has reduced pressure capability to reduce the pressure applied to the extend side of the cylinder.

To ensure the cleanliness and correct flow of the oil in the system, the oil was filtered out of the pump then again before returning it back into the reservoir.

The project focussed on responsible waste management and the reuse of materials. And as such Fuchs PlantoHyd 32 was selected as the hydraulic fluid with its environmental credentials and often use in natural water source sectors. The unit is also built into a bunded frame providing containment and an extra layer of protection in the unlikely event of leaks or spills.

The completed project, which has been nominated for a number of awards, contributed more than £600,000 into the local economy and supported wider social benefits. The new tidal gates in Truro will protect 185 homes and businesses from flooding for the next 30 years, with minimal impact on the environment.

Explore our case studies for more project examples of our capabilities and contact us to discuss your requirements.

Follow us on LinkedIn to be kept up to date on this project and others.