- Client:

- Royal Haskoning

- Date:

- September 2002

- Scope of work:

- Design, Manufacture, Installation, Commission

- Location:

- Dún Laoghaire, Ireland

- Specs:

2 complete systems for port and starboard sides.

2 x Hydraulic power units.

20 x Hydraulic cylinders.

76.2 kW of installed power.

4 Main pumps, running and standby.

210 L/min/pump.

Specially containerised for transportation and installation.

Design for the environment incl full stainless steel pipe installation.

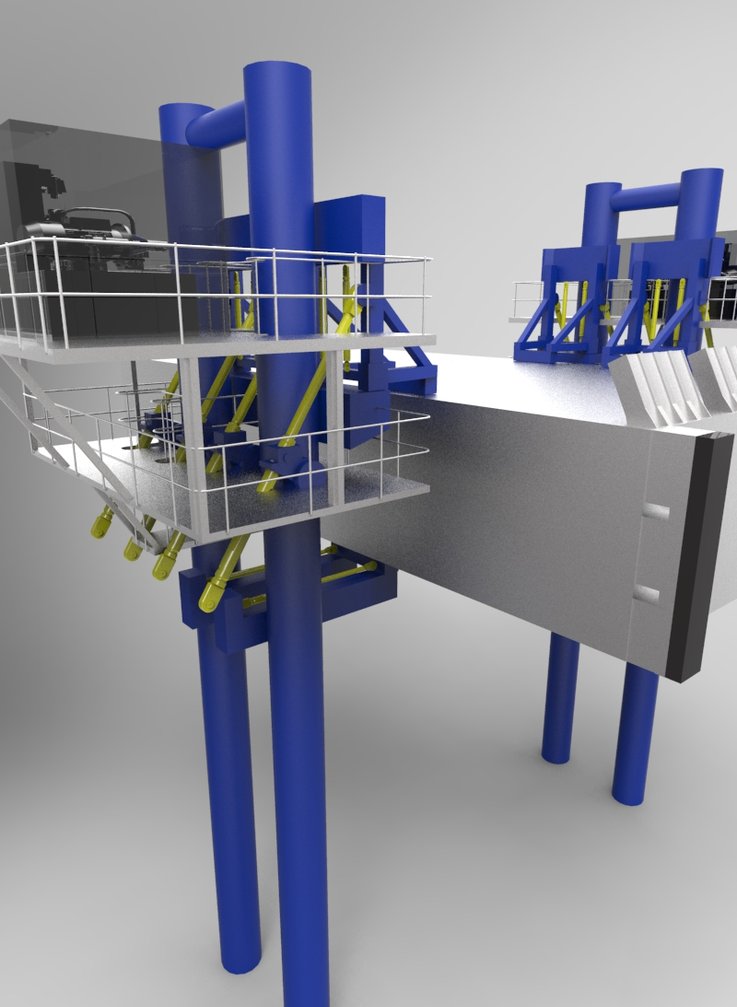

HSS LINKSPAN RESTRAINT SYSTEM

- Overview:

The linkspan is a revolutionary device that locks a ship stern onto the berth without the use of mooring ropes. Originally, the linkspan was hinged to the shore and floated freely at the seaward end, once the vessel had departed. However, over time this proved to cause excessive wear on the unit and a design solution was required to hold the linkspan in place and ensure long term service life.

Together with Royal Haskoning, IMH developed an innovative system to overcome this problem, providing the design, manufacture, installation and commissioning for the complete hydraulic systems, including a facility to accommodate both normal and storm positions, and designed and built in accordance with Lloyds classification of linkspans.

“Now that the new linkspan restraint system is operational and linkspan hinge pins have been successfully replaced, I wanted to take the opportunity to thank you for the hard work put in by your team. The project was particularly complex and your contribution to the project was greatly appreciated. We look forward to having the opportunity to work with you again.”

Jonathan Tyler, Maritime Group Director, Royal Haskoning